Product Category

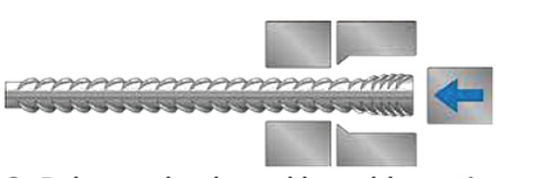

Upsetting Forged Rebar Couplerrebar couplers offer a full strength connection together with enhanced fatigue resistance.

Upsetting Forged Rebar Coupler

Product Characteristic

_1767547088.webp) | Product name | Upsetting Forged Rebar Coupler | Brand Name | ADTO/OEM |

Material | 45C, 50C, 40CR, 42CR | Surface | Black /Electro Galvanized | |

Standard | ACl 318, JGJ 107, UBC 1997 BS 8110, NF 35-20-1DI ,ISO 15835 | Craft | CNC, Tapping | |

Place of Origin | China (Mainland) | Certification | ISO, DCL, UK |

Introduction:

| Upsetting forged rebar couplers offer a full strength connection together with enhanced fatigue resistance. They are suitable for projects of any size, including those requiring a high volume of couplers, such as road and rail bridges. Each end of the rebar to be joined is cut square and enlarged using a cold forge process. A thread is then formed on the enlarged bar end using a thread rolling machine. The thread is such that the cross-sectional area of the bar ends are not reduced ensuring the strength of the connection matches or exceeds that of the parent bars. |

Type:

Standard Rebar Coupler

| Transition Rebar Coupler

|

Position Rebar Coupler

| Flare Rebar Coupler

|

Extended Rebar Coupler

| CC Rebar Coupler

|

Hex Rebar Coupler

| QT Rebar Coupler

|

Galvanized Rebar Coupler

| Epoxy Rebar Coupler

|

How to Connected

STEP 1 Rebar end cut square with band saw

|

STEP 2 Enlarging ends of reinforced bars by cold upsetting (Rebar Upset forging Machine )

|

STEP 3 Threading parallel threads rebar end by DLADTO Rebar Thread Cutting Machine

|

Product Advantage:

No reduction of bar cross-section area and bar –break feature |

Matched Machine

Upsetting Forged Machine

| Threading Cutting Machine

|

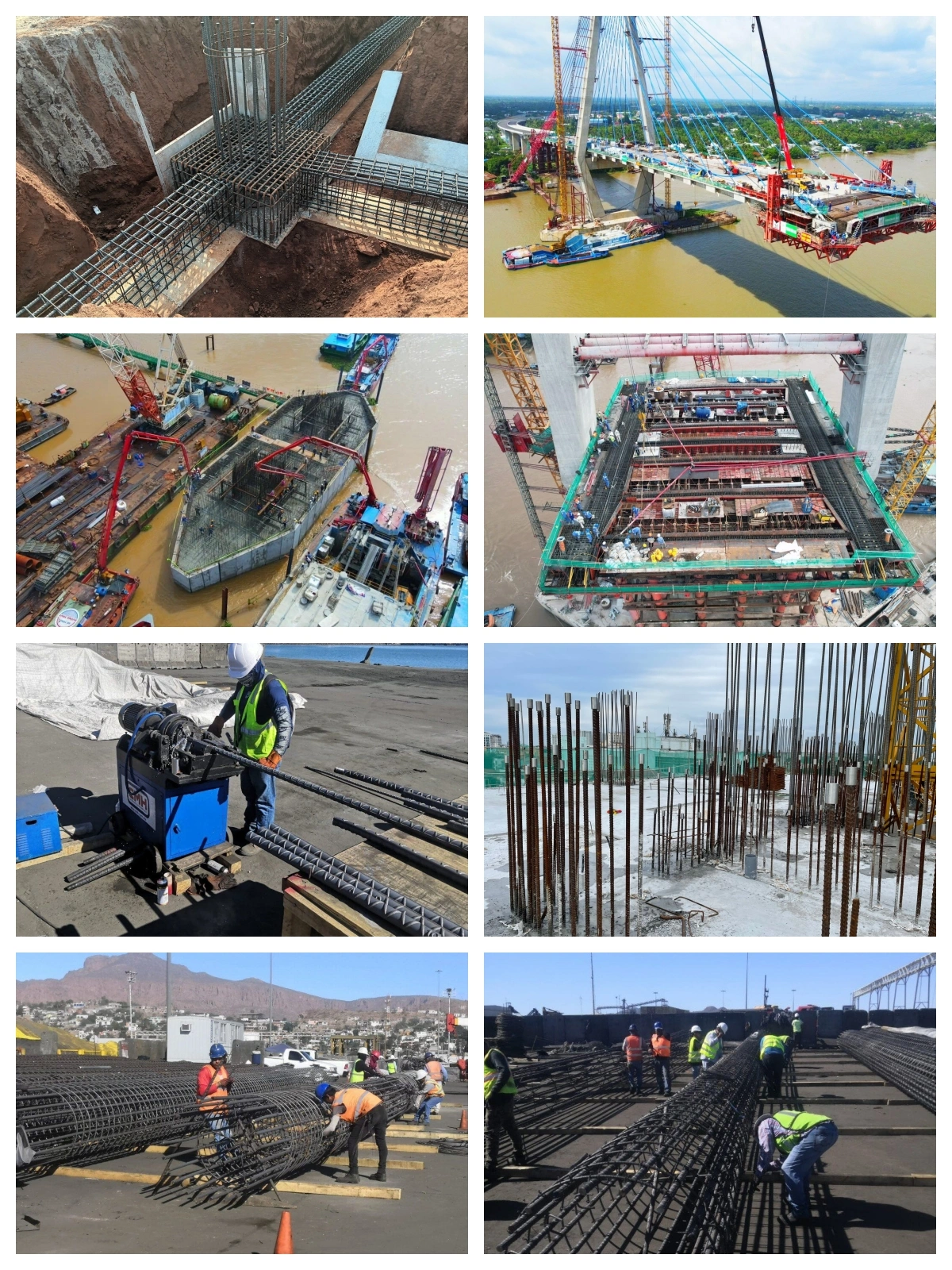

Project Picture

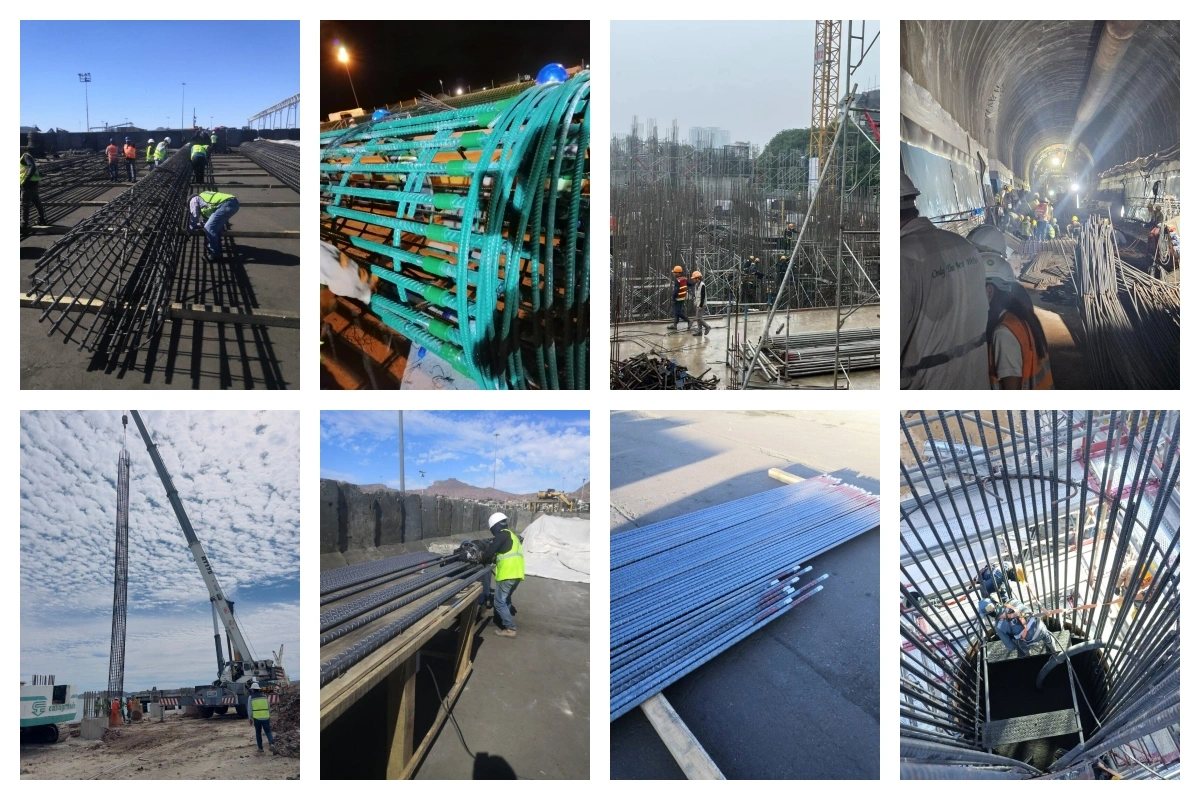

Certification

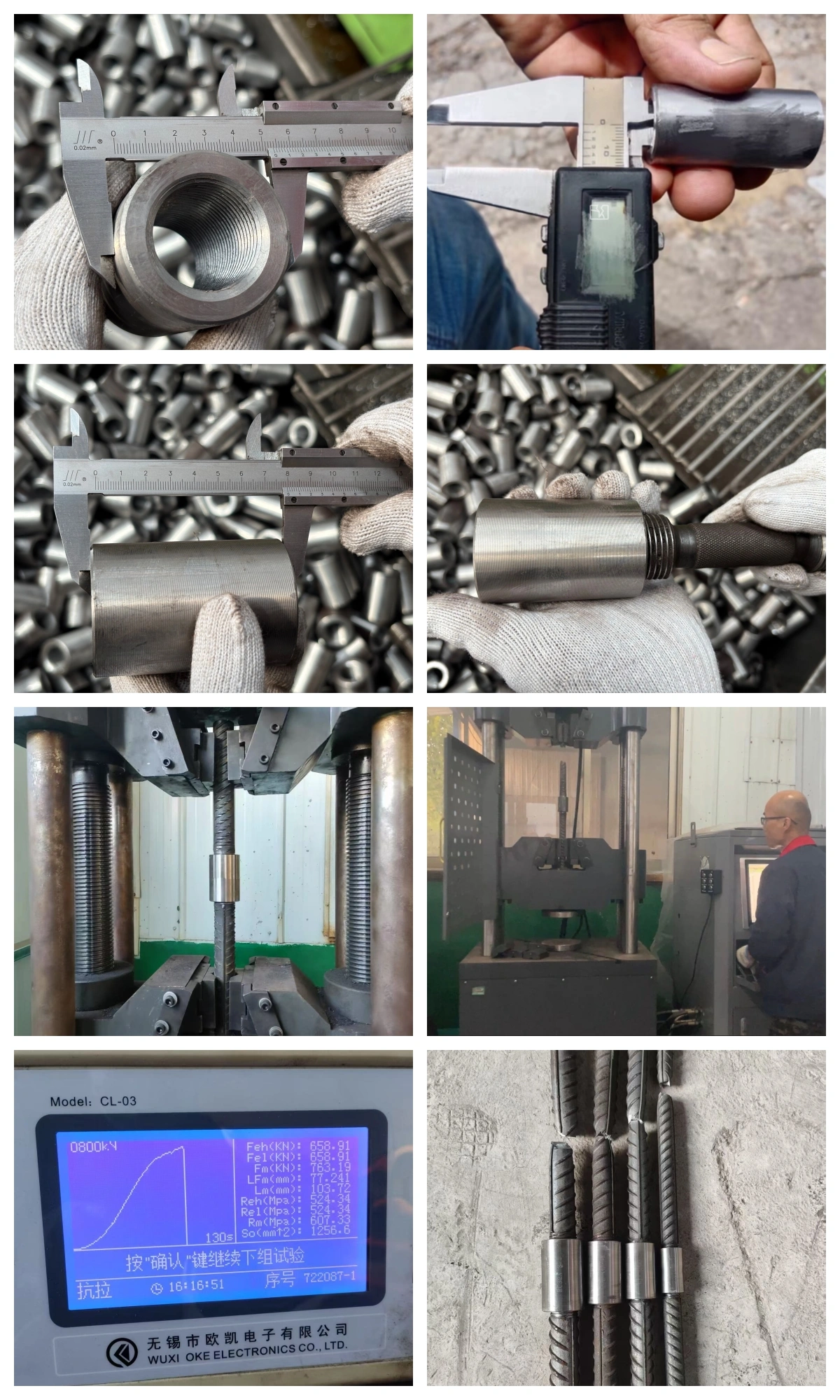

Test Picture

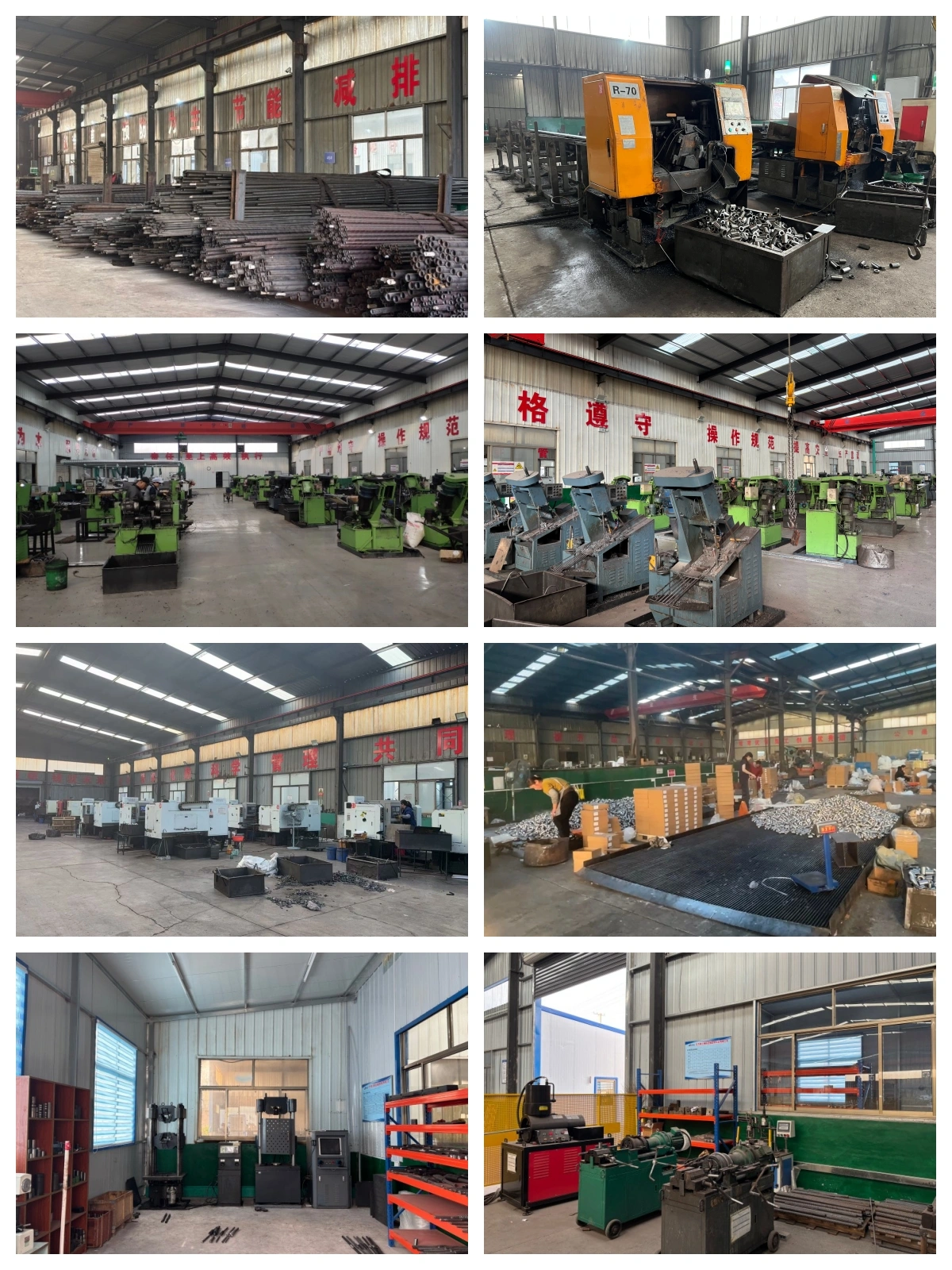

Factory Picture

Package

|

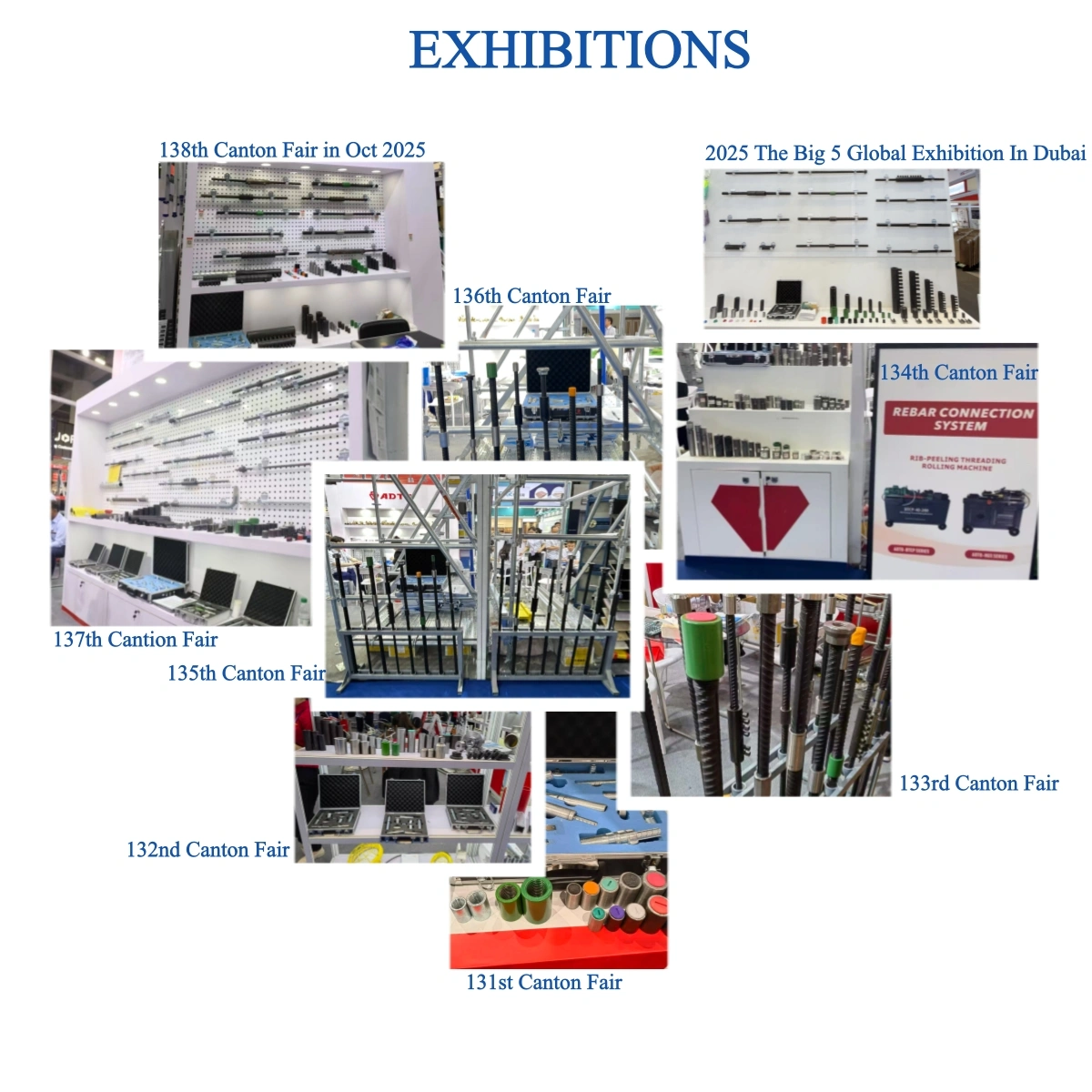

Fair Information

_1767547386.webp)

_1767547435.webp)

_1767548017.webp)

_1767613872.webp)

_1767610192.webp)

_1767610484.webp)

_1767611394.webp)

_1767611654.webp)

_1767611706.webp)