Product Category

Rebar Terminator is a mechanical device designed to enhance the anchoring performance of steel reinforcement bars. By expanding the bearing area at the end of the reinforcement bar, it converts the tensile force of the bar into compressive pressure on the concrete, significantly improving anchoring efficiency and reliability. This product is widely used in conditions such as densely packed reinforcement in joint areas or insufficient anchorage length, making it an essential reinforcement component in modern reinforced concrete structures.

Rebar Terminator

Product Characteristic

_1767784200.webp) | Product name | Rebar Terminator | Brand Name | ADTO/OEM |

Material | 45C, 50C, 40CR, 42CR | Surface | Black /Electro Galvanized | |

Standard | ACl 318, JGJ 107, UBC 1997 BS 8110, NF 35-20-1DI ,ISO 15835 | Craft | CNC, Tapping | |

Place of Origin | China (Mainland) | Certification | ISO, DCL, UK |

Introduction:

| Rebar Terminator is a mechanical device designed to enhance the anchoring performance of steel reinforcement bars. By expanding the bearing area at the end of the reinforcement bar, it converts the tensile force of the bar into compressive pressure on the concrete, significantly improving anchoring efficiency and reliability. This product is widely used in conditions such as densely packed reinforcement in joint areas or insufficient anchorage length, making it an essential reinforcement component in modern reinforced concrete structures. |

Type Picture :

|

|

|

|

How to Connected

STEP 1 :Rib Peeling: A specialized rib-peeling and thread-rolling machine is used to precisely remove the longitudinal and transverse ribs from the ends of the reinforcing bars, forming a smooth and regular cylindrical surface. This step eliminates interference from the ribs during subsequent rolling, ensuring a consistent base diameter.

|

STEP 2 :Thread Rolling: The cylindrical section after rib peeling undergoes cold-rolling via thread-rolling wheels. Under plastic deformation, the metal fibers are redistributed and strengthened, forming continuous, dense, high-strength threads. This process does not involve metal cutting but rather enhances the metal's properties.

|

STEP 3 :Reba coupler Connection: The two reinforcing bars with processed threads are screwed into the sleeve. A specialized wrench is used to tighten them until the bar ends are firmly pressed against each other inside the sleeve, enabling the transfer of force.

|

Product Advantage:

Stress Dispersion: Converts concentrated stress into distributed surface loads. Anchorage Enhancement: Increases pull-out bearing capacity by 30%–50%. Space Saving: Reduces reinforcement lap length by 40%–60%. Seismic Performance Improvement: Enhances ductility and energy dissipation capacity in joint areas. |

Matched Machine

Threading Roller Machine

|

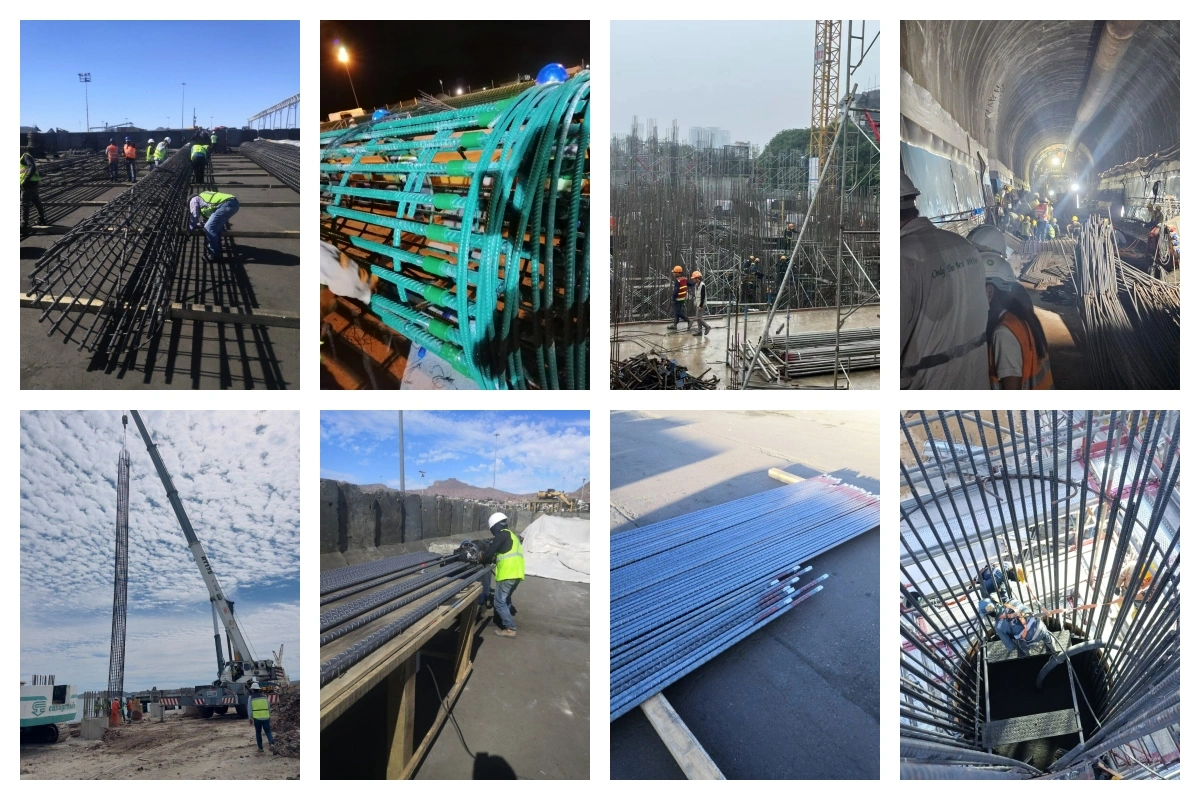

Project Picture

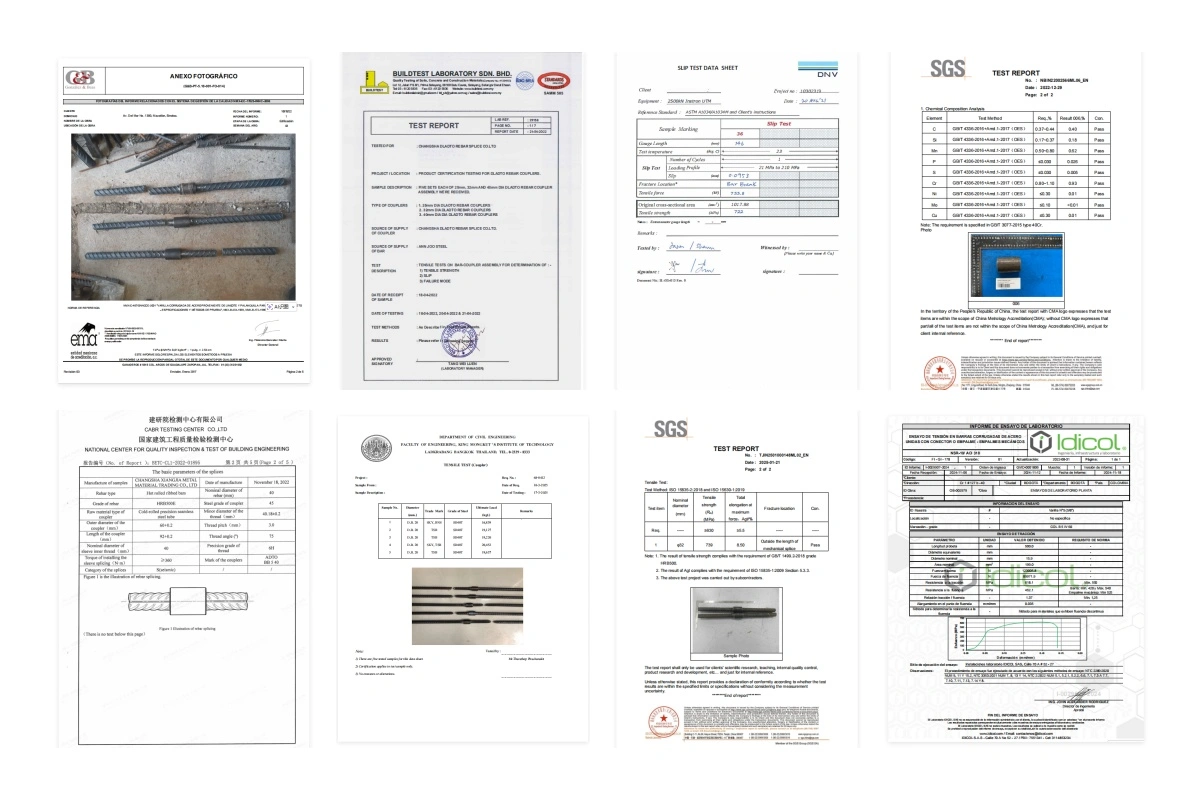

Certification

Test Picture

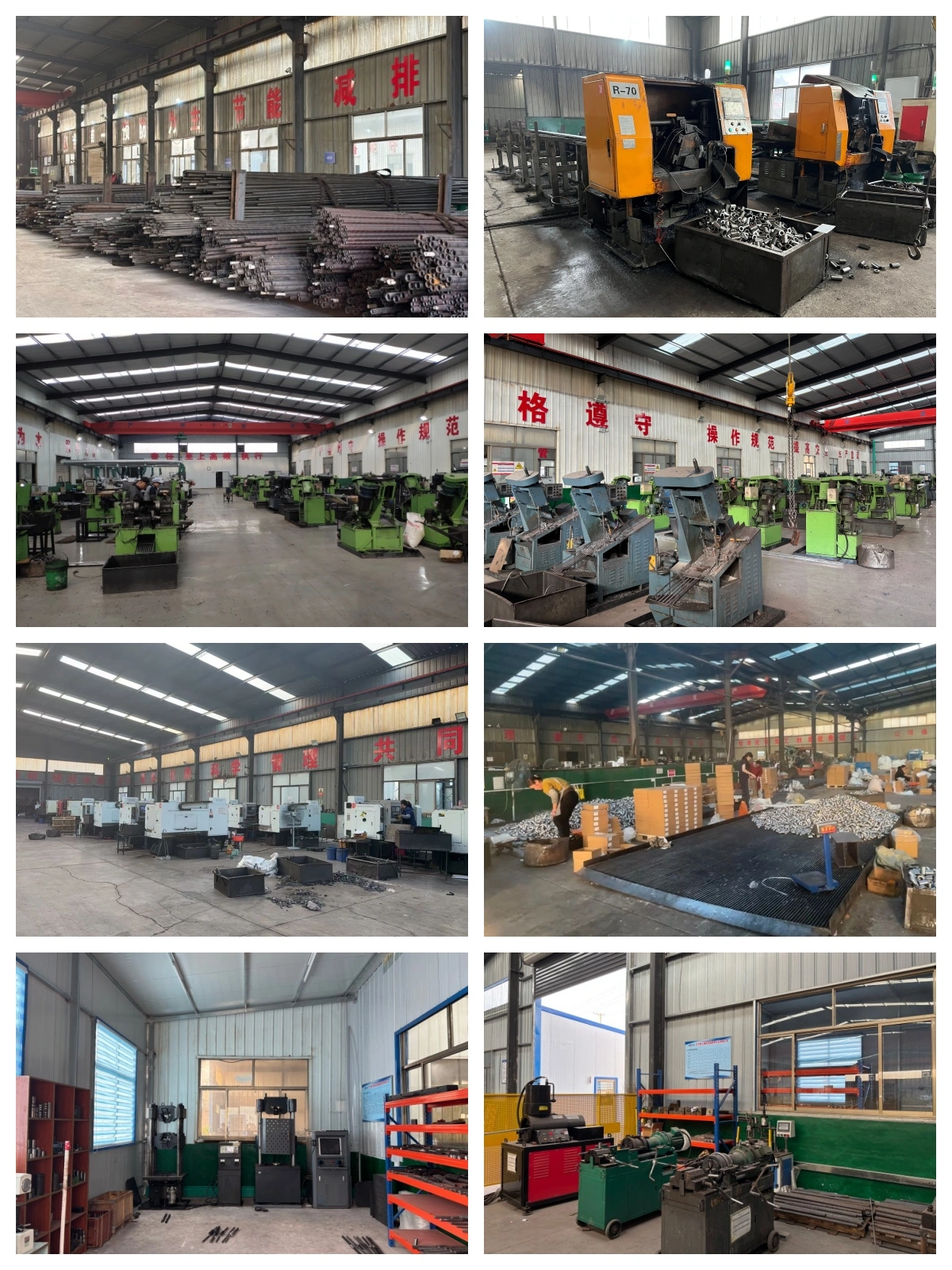

Factory Picture

Package

|

Fair Information

_1767784200.webp)

_1767784200.webp)

_1767784200.webp)