Product Category

Grouting rebar coupler is a prefabricated component used for the mechanical connection of steel reinforcement bars, widely applied in precast concrete structures. It achieves high-strength and highly reliable connections between rebars by injecting high-strength, micro-expansive special cement-based grout into the annular gap between the sleeve and the rebars, and allowing the grout to harden. This product is a core connecting component in prefabricated buildings, and its performance is directly related to the safety and stability of the overall structure.

Grouting Rebar Coupler

Product Characteristic

| Product name | Grouting Rebar Coupler | Brand Name | ADTO/OEM |

Material | 45#,Q355B | Surface | Black | |

Standard | ACl 318, JGJ 107, UBC 1997 BS 8110, NF 35-20-1DI ,ISO 15835 | Craft | / | |

Place of Origin | China (Mainland) | Certification | ISO, DCL, UK |

Introduction:

Grouting rebar coupler is a prefabricated component used for the mechanical connection of steel reinforcement bars, widely applied in precast concrete structures. It achieves high-strength and highly reliable connections between rebars by injecting high-strength, micro-expansive special cement-based grout into the annular gap between the sleeve and the rebars, and allowing the grout to harden. This product is a core connecting component in prefabricated buildings, and its performance is directly related to the safety and stability of the overall structure. |

Part Type

|

|

|

|

How to Connected

Preparation: The Coupler is pre-embedded in the precast component, and on-site, the other rebar is inserted into the coupler cavity. Grouting: The mixed grout is pumped into the coupler through the grout inlet using a specialized grouting machine. Filling: Under pressure, the grout fills all gaps between the rebar and the inner wall of the sleeve and flows out uniformly from the outlet. Curing and Force Transfer: Once the grout hardens, effective force transmission is achieved through the triple mechanical interlocking action between the ribs/grooves on the inner wall of the sleeve and the grout, and between the grout and the ribs on the surface of the rebar.

|

Product Advantage:

High Connection Strength: It achieves an equal-strength connection with the connected steel bars, with the joint strength not lower than that of the base material of the bars. Excellent Seismic Performance: It demonstrates good ductility and cyclic tension-compression performance, meeting seismic design requirements. Strong Applicability: It is suitable for various specifications of ribbed steel bars such as HRB400 and HRB500. Convenient Construction: On-site work primarily involves grouting, which is relatively simple and less affected by weather and environmental conditions (construction should be conducted at temperatures above 5°C). Controllable Quality: By regulating the fluidity, strength, and grouting density of the grouting material, the stability and reliability of the connection quality are ensured. |

Matched Machine

Grouting Machine

|

Project Picture

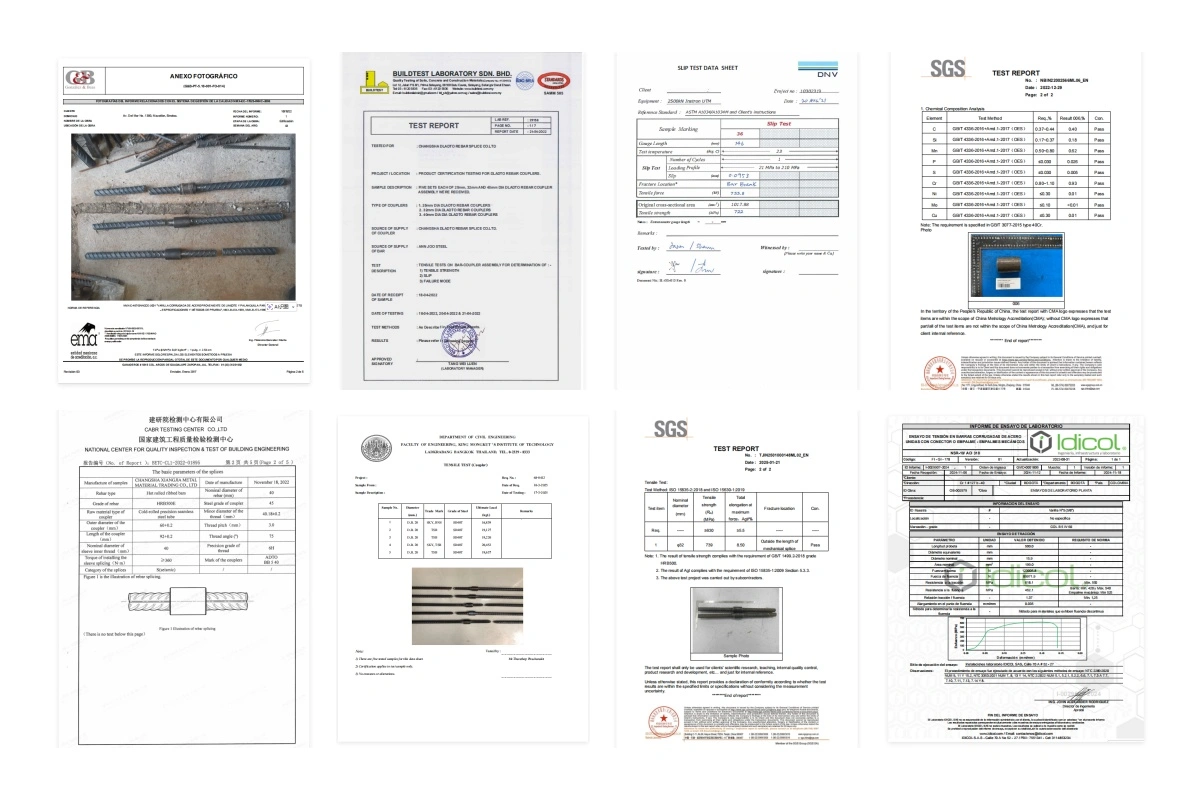

Certification

Test Picture

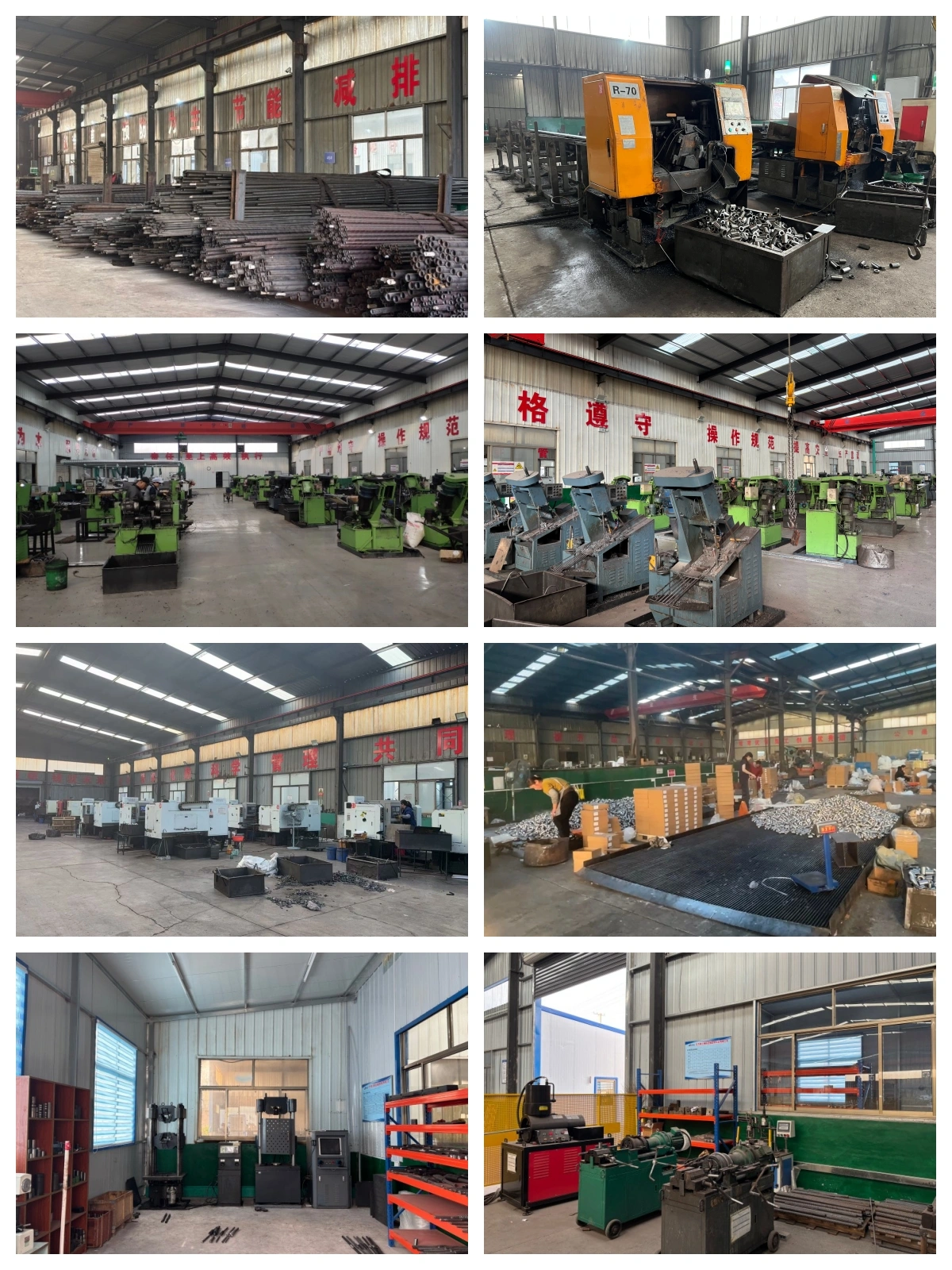

Factory Picture

Package

|

Fair Information

(1)_1767698742.webp)

_1767699502.webp)

_1767698743.webp)

_1767699637.webp)

_1767706509.webp)

_1767706603.webp)

_1767706634.webp)

_1767706681.webp)