Product Category

Weldable Rebar coupler is a mechanical connection device used for splicing steel reinforcement bars through welding. Manufactured from high-quality structural steel with factory-prefabricated welding grooves, it allows two rebars to be welded to the sleeve either on-site or in the factory, forming a continuous force-transferring rigid joint. This product is suitable for all engineering scenarios permitted by the reinforcement welding operation specifications, particularly for large-diameter rebars, connections between different types of steel, and complex joint areas.

Weldable Rebar coupler

Product Characteristic

_1767793909.webp) | Product name | Weldable Rebar coupler | Brand Name | ADTO/OEM |

Material | 45C, 50C, 40CR, 42CR | Surface | Black /Electro Galvanized | |

Standard | ACl 318, JGJ 107, UBC 1997 BS 8110, NF 35-20-1DI ,ISO 15835 | Craft | CNC, Tapping | |

Place of Origin | China (Mainland) | Certification | ISO, DCL, UK |

Introduction:

| Weldable Rebar coupler is a mechanical connection device used for splicing steel reinforcement bars through welding. Manufactured from high-quality structural steel with factory-prefabricated welding grooves, it allows two rebars to be welded to the sleeve either on-site or in the factory, forming a continuous force-transferring rigid joint. This product is suitable for all engineering scenarios permitted by the reinforcement welding operation specifications, particularly for large-diameter rebars, connections between different types of steel, and complex joint areas. |

Type Picture :

|

|

How to Connected

STEP 1 :Rib Peeling: A specialized rib-peeling and thread-rolling machine is used to precisely remove the longitudinal and transverse ribs from the ends of the reinforcing bars, forming a smooth and regular cylindrical surface. This step eliminates interference from the ribs during subsequent rolling, ensuring a consistent base diameter.

|

STEP 2 :Thread Rolling: The cylindrical section after rib peeling undergoes cold-rolling via thread-rolling wheels. Under plastic deformation, the metal fibers are redistributed and strengthened, forming continuous, dense, high-strength threads. This process does not involve metal cutting but rather enhances the metal's properties.

|

STEP 3 :Reba coupler Connection: The two reinforcing bars with processed threads are screwed into the sleeve. A specialized wrench is used to tighten them until the bar ends are firmly pressed against each other inside the sleeve, enabling the transfer of force.

|

Product Advantage:

Wide Applicability: Suitable for various ribbed/smooth steel bars ranging from Φ14mm to Φ50mm. Dissimilar Material Connection: Enables equal-strength connections between steel bars of different strength grades. Spatial Flexibility: Low requirements for installation space, allowing welding from multiple angles. Visual Inspection: Weld quality can be directly evaluated through non-destructive testing. |

Matched Machine

Threading Roller Machine

|

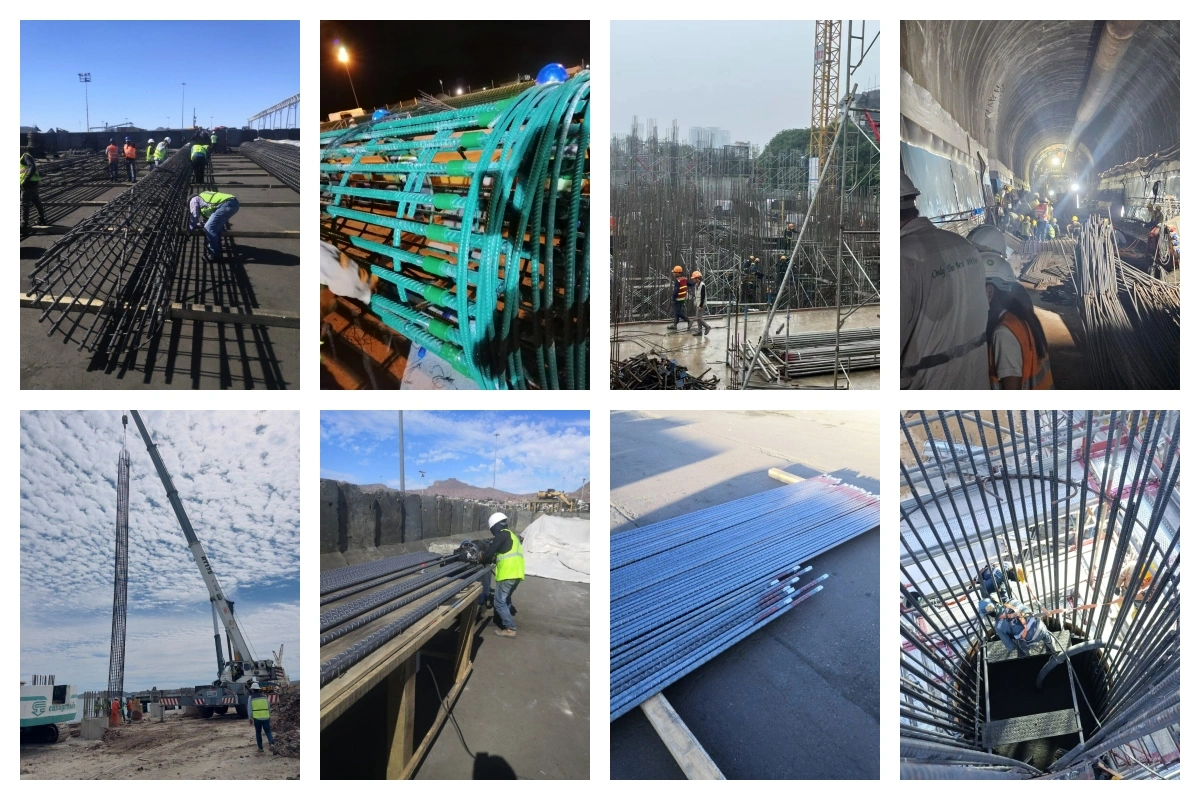

Project Picture

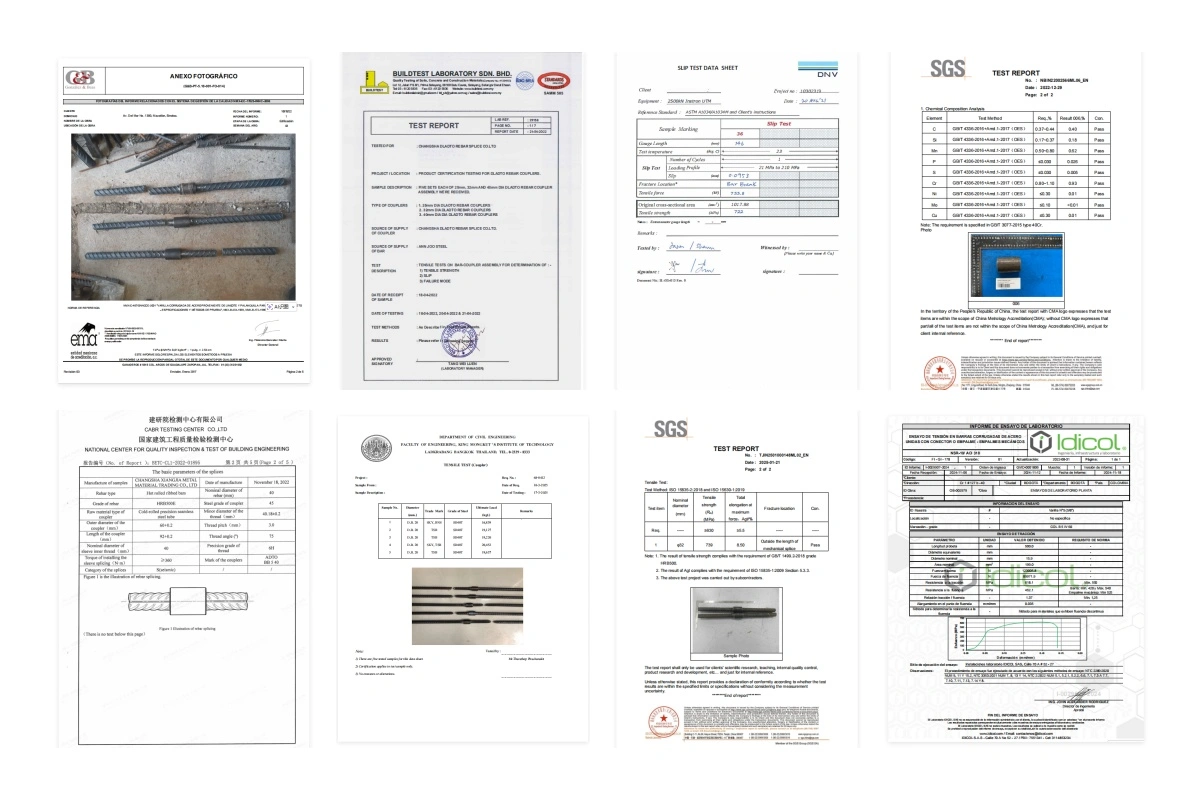

Certification

Test Picture

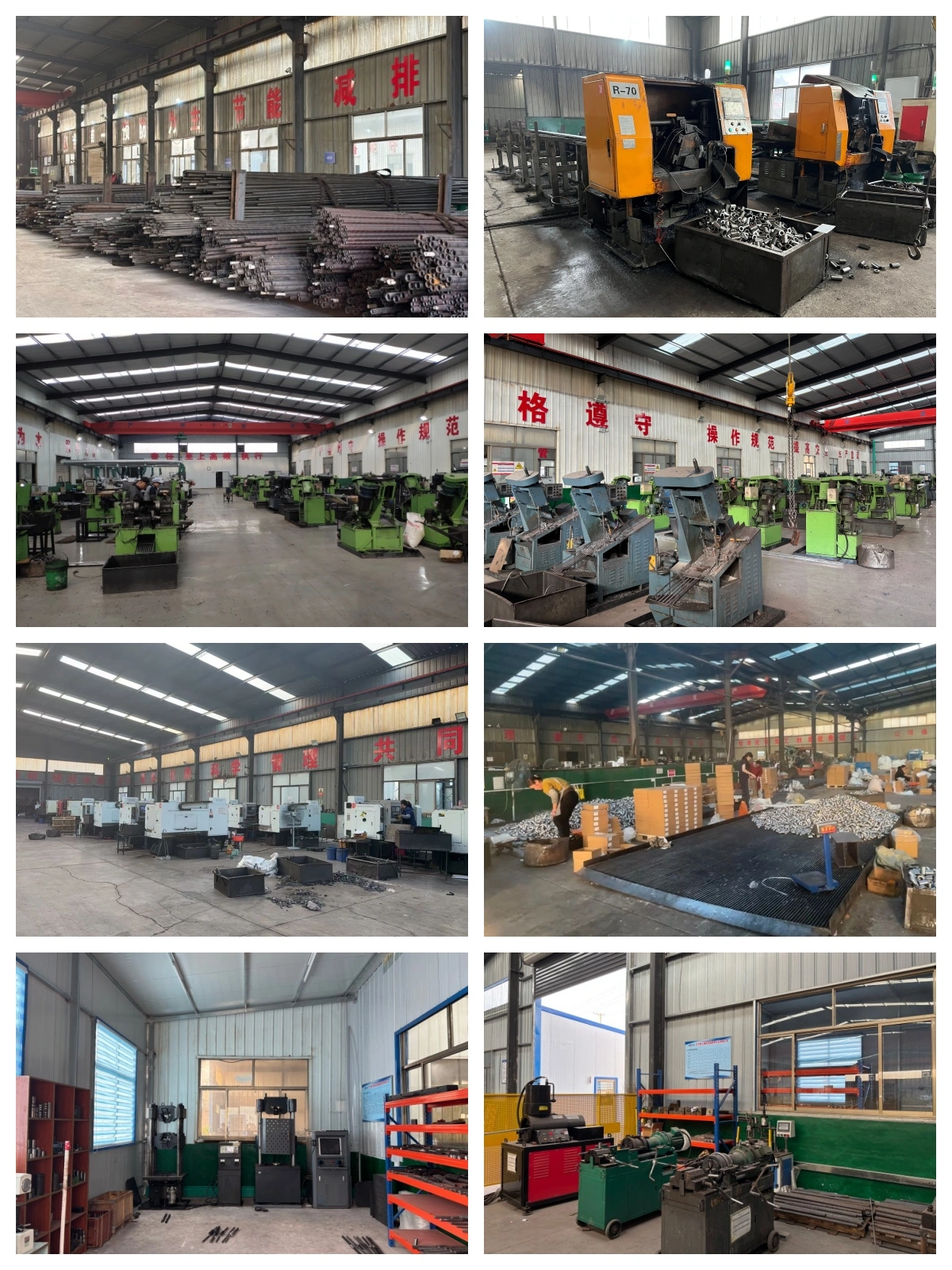

Factory Picture

Package

|

Fair Information

_1767793909.webp)